This I/O device allows a model running in SimWB to communicate with Senso Wheel and Pedals through RTDB. Using this, users can provide steering and pedal input to their models via SensoWheel. We have tested the SD-LC wheel & SensoPedals Pro. While other devices are expected to work, they are not tested.

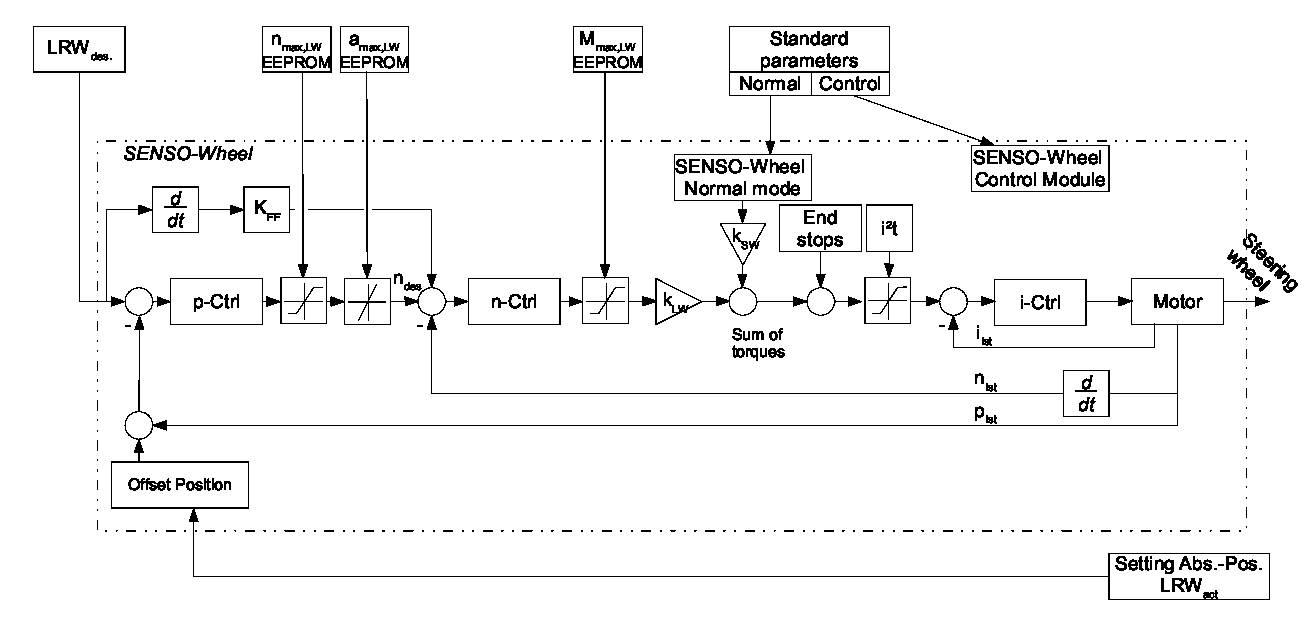

It also supports position and velocity control of SensoWheel (SensoWheel Active Position Control). Active position control is especially vital for ADAS applications.

To run this I/O task, you need to have PEAK-CAN USB device.

CS-GC-CAN-USB

WCS-GC-CAN-USB

ICS-SWB-1245.

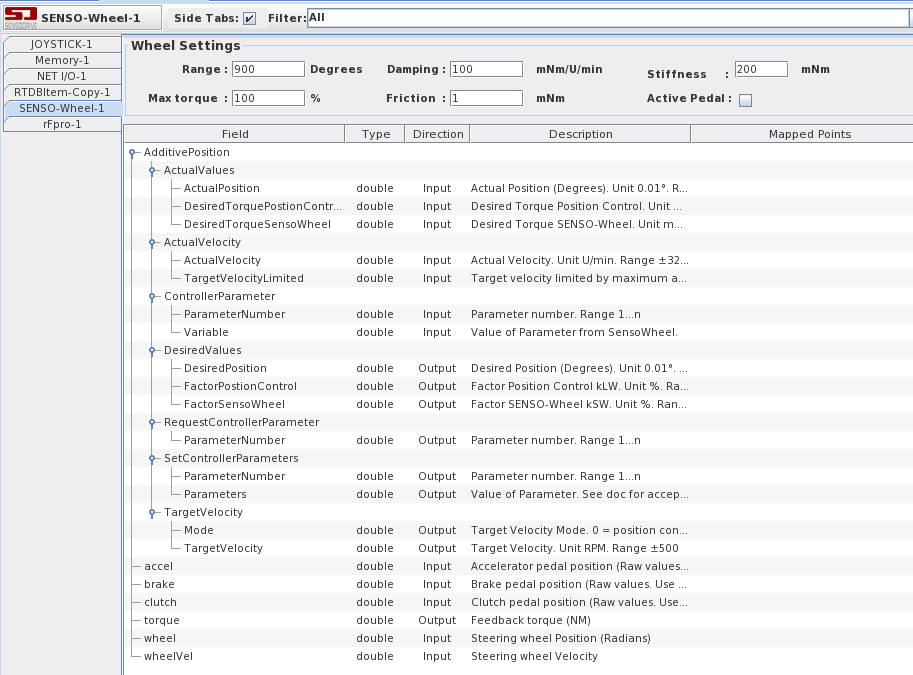

This pane allows the user to set the wheel parameters to match that of the wheel that needs to be emulated.

Rotation range of the Senso Wheel. Default is 720 Degrees. Allowed range is 90 to 1440 degrees.

This defines the auto centering maximum torque that the Senso Wheel will output. Default is 100 %.

This defines the damping factor is used by the Senso Wheel in mNm/U/min. Default is 100 mNm/U/min. Allowed range is 0 to 500 mNm/U/min.

This defines the friction factor is used by the Senso Wheel. Default is 1 mNm. Allowed range is 0 to 5000 mNm.

This defines the stiffness factor is used by the Senso Wheel in mNm/deg. Default is 200 mNm/deg. Allowed range is 0 to 2500 mNm/deg.

Parameter of the SensoWheel program.

Type of data the field contains.

Direction of the point. Can be input or output.

Description of the field.

Shows the mapped Input/Output point(s) of a field.

To map a field to a channel, select a field on the left side of the I/O Mappings form, then click on a check box for an I/O point on the right side of the form. See I/O Mappings... for details.

AdditivePosition.DesiredValuesAllows users to set the desired position. The factors kSW and kLW control the weight for normal mode and position control torques respectively. Superposition of both torques can be achieved by using non-zero values for these parameters. If this CAN message is not sent, the SENSO-Wheel SD-LC behaves like the standard model without additive position control. In other words, kSW = 100 and kLW = 0. If you are setting the values via RTViewer, it is recommended to use RTForms to set all the values simultaneously since we send CAN messages as soon as we detect any changes. DesiredPositionDesired Position (Degrees). Unit 0.01°. Range ±144000. FactorSensoWheelFactor SENSO-Wheel kSW. Unit %. Range 0-200. FactorPostionControlFactor Position Control kLW. Unit %. Range 0-200. AdditivePosition.ActualValuesSensoWheel sends the actual position using this message. It usually sends one reply whenever we set a desired position. It is possible that the wheel did not reach the final position when we receive this message. The actual position can be read out from the CAN message of the SENSO-Wheel Normal Mode continuously. In other words, 'wheel' variable above should give the current position contiguously. Please note that wheel is in radians and desired position is in 0.01 degrees. ActualPositionActual Position (Degrees). Unit 0.01°. Range ±144000. DesiredTorqueSensoWheelDesired Torque SENSO-Wheel. Unit mNm. Range -32768 - +32767. DesiredTorquePostionControlDesired Torque Position Control. Unit mNm. Range -32768 - +32767. AdditivePosition.TargetVelocityAllows users to set the desired velocity. When this message is received by SensoWheel, the position controller is switched off and a desired velocity is set. If you are setting the values via RTViewer, it is recommended to use RTForms to set all the values simultaneously since we send CAN messages as soon as we detect any changes. TargetVelocityTarget Velocity. Unit RPM. Range ±500. ModeTarget Velocity Mode. 0 = position controller, 1 = velocity controller. AdditivePosition.ActualVelocitySensoWheel sends the actual velocity using this message. It usually sends one reply whenever we set a desired velocity. The actual velocity can be read out from the CAN message of the SENSO-Wheel Normal Mode continuously. In other words, 'wheelVel' variable above should give the current velocity contiguously. TargetVelocityLimitedTarget velocity limited by maximum acceleration and maximum velocity . Unit U/min. Range ±500. ActualVelocityActual Velocity. Unit U/min. Range ±32767. AdditivePosition.SetControllerParametersAllows users to set the desired parameters. If you are setting the values via RTViewer, it is recommended to use RTForms to set all the values simultaneously since we send CAN messages as soon as we detect any changes. Or you can change the parameter number first before changing the parameter value. This way, we will only change the desired parameter and not old parameter. ParameterNumberParameter number. Range 1...n. ParametersValue of Parameter. See doc for acceptable values. AdditivePosition.RequestControllerParameterAllows users to request the value of a the parameter. ParameterNumberParameter number. Range 1...n. AdditivePosition.ControllerParameterSensowheel sends the requested parameter value and the parameter number. ParameterNumberParameter number. Range 1...n. VariableValue of Parameter from SensoWheel. |

|

If there are issues with the Senso Wheel and Pedals not working or being detected by SimWorkbench, please verify that the Senso Wheel and Pedals are working correctly with these instructions here.

|

RVDT:Out and NAI_64DL1 | SOMEIP |

|